-

WOODWORKING

-

METALWORKING

- PLASTICS / COMPOSITES

- DUST/CHIP SYSTEMS

-

POSITIONERS

-

PARTS AND TOOLING

-

SUPPORT

-

TRAINING

-

PRE-OWNED MACHINES

$321,812.00

| /

To see all versions of the MASTER RT and options Click here for Brochure

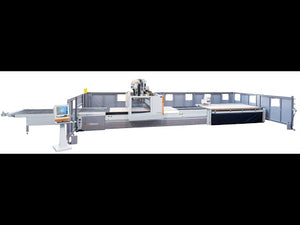

JET MASTER RT 16/3 CNC CELL with Labeling Device

Busellato uses 3-dimensional solid modeling systems to design its working centers which are built with a mobile beam and stationary basement. The beam moves in a longitudinal direction with respect to the basement (X axis) and supports a pair of carriages which determine the movement of the Y and Z axes. The X and Y axes define a plane parallel to the floor and the Z axis moves up and down perpendicular to this plane. This configuration allows a remarkable reduction in the machine’s overall size and improves the machine’s performance and functionality. The basement and the beam are made of electrically welded steel and are ribbed and strengthened internally to guarantee maximum rigidity even under intense working. The structures undergo a thermally-controlled normalization cycle.

QUALITY CONTROL

All phases of assembly undergo conformity checks according to special testing procedures. The alignment of all the linear guides is carried out using an electronic level guaranteeing straightness and parallelism tolerances to be within 0.02 mm per linear meter. On all machines, positioning precision and bi-directional repeatability of the axes is checked using an interferometer laser system. Bi-directional positioning precision is guaranteed within a tolerance of ±0.05 mm. To complete the dynamic tests carried out on the machines, the interpolation of the axes (circularity) is tested with the Ball-Bar Renishaw device. An electrical test of the whole system is carried out on each machine according to CEI EN 60204-1 legislation.

LINEAR MOTION SYSTEMS

X AXIS - Movement of the X axis is by rack and pinion with convex, helicoidal teeth, made of hardened and tempered steel which undergoes a thermal carburizing treatment and successive hardening. A lubricating film is applied to the teeth, eliminating the need for lubrication during the life of the machine. The pinion is splined directly on a high precision planetary gearbox. Precision of the movement along the X axis is guaranteed by a measurement with laser instrumentation and software management of the calibration curve to guarantee an absolute measurement with time. The mobile beam moves on high precision pre-loaded ball runner blocks and linear guides made of rectified and hardened steel. Ball runner blocks for all axes are equipped with a seal guaranteeing maximum protection from dirt and dust.

Y and Z AXES - The carriages for these axes are made from an aluminum alloy with highly rigid mechanical properties. Movement of these axes is by ball nut with pre-loaded lead screw in order to guarantee high speeds with minimal wear. The carriages are mounted on pre-loaded ball runner blocks which slide on very high precision linear guides made of rectified and hardened steel. Z axis motor and ball screws are sized to avoid the need for pneumatic assistance. All axes are driven by AC brushless motor fed and controlled by digital drives.

DUST EXTRACTION

Busellato installs a centralized dust extraction system, with a single large pipe mounted on the head. The system automatically diverts collection between the main electrospindle and drilling head to maximize efficiency. In addition, Busellato supplies a 4-way VECTOR air blast system consisting of four pipes pointing in + and - X and + and - Y direction to blow air behind the cutting tool to greatly enhance dust extraction. The NC control automatically manages the supply of air to one of the four pipes according to the direction the machine is moving.

LUBRICATION

The machine is equipped with a central lubrication system with progressive distribution. The system has a single feeding point for the group of distributors, which send automatically and safely, an adequate volume of lubrication to each lubrication point. The grease reservoir and pump are permanently attached to the machine, eliminating the need to store and maintain a separate grease gun. The control software alerts the operator when lubrication is necessary.

MACHINE SAFETY

The machine is equipped with front safety mats, rear and lateral fence, and head shroud cover, as well as these additional safety systems: push buttons for emergency stop, software and hardware to monitor the safety distance, check sensors for the vacuum and compressed air level.

ELECTRICAL CABINET

The electrical cabinet is integrated in the left hand side of the machine base and is tested according to the strict international regulations (EN 60204).

INVERTER

The BUSELLATO JET ROUTER employs a heavy duty, digital, programmable frequency static converter (inverter) and includes control that the motor has stopped, braking resistance and automatic reset in case of emergency.

MOBILE PC CONSOLE

Mobile console for PC allows the operator to position the programming and control station according to the workflow of materials at any given time. The control PC consists of:

- Windows XP operating system

- Pentium Dual Core processor

- 1 Gb RAM memory

- 80 Gb Hard Drive

- High resolution 19” LCD color screen (1280x1024)

- DVD/CD-RW 48X Burner

- 1 serial port for communication with the inverter and 1 parallel port for peripheral external connections

- 5 USB 2.0 ports, with one externally mounted on the control panel for easy access

- 1 Ethernet RJ45 port for connecting to office network

TELE-SERVICE VIA INTERNET

Allows remote connection between the machine’s PC and Casadei-Busellato’s Authorized Service Center allowing direct intervention on the control for checking parameters of the whole machine, single programs and installation of eventual software updates. Internet access and connection is the responsibility of the customer.

|

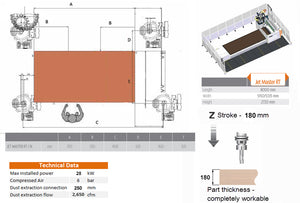

TECHNICAL FEATURES |

|

Working Field X 3710mm 146” |

|

Working Field Y 1620mm 63.78” |

|

Z axis stroke 180 mm 7.09” |

|

Linear Speed X/Y/Z 60/50/15 m/min 196/164/49 ft/min |

|

Vector Speed 78 m/min 255 ft/min |

|

|

|

Electrical service requires 3 phase power |

|

Amperage for machine (@17kW load) 208V/230V/460V 48 amp/47 amp/26 amp |

|

Amperage for ONE vacuum pump 208V/230V/460V 30 amp/28 amp/14 amp |

|

Dust Collection |

|

Connection dia. to machine head 250mm 9.8” |

|

Dust extraction air velocity 29 m/sec 5708 ft/min |

|

Dust extraction rate 5300m³/hr 3120 cfm |

|

Compressed Air, dry and filtered |

|

Line diameter 19mm ¾” |

|

Pressure 6.2bar 90 psi |

|

Rate 210L/min 7 cfm |

VACUUM TABLE AND SYSTEM

NESTING ROUTER TABLE

Router table is 146” x 52” with rear, LH and RH lateral stops and is machined from heavy-duty, thick phenolic with gasket channels throughout the table for re-configuring the vacuum area. The rectangular grid is made of 60mm sections. NC controlled retractable stops (8 rear stops (X) and 4 lateral ones (Y) 2 on the right/ 2 on the left) Total 12 stops. Stops stroke 90 mm.

FB1368 Additional front reference stops (x=3710mm)

Additional, retractable reference stops controlled by NC.

Including:

Nr. 8 front stops

- 2 lateral stop l/h ,

- 2 lateral stop r/h .

Total 12 stops.

FB1360 Sixteen (16) WORKING AREAS

The vacuum areas are manually selected or from PC and allow to adapt the vacuum area to the piece dimensions, maximizing the seal. The working table is dived into 4 horizontal and 4 vertical areas.

FB1213 High power vacuum of 500/600 m3/h 50/60 Hz

(2) 250 m3/h oil less vacuum pumps, complete with:

- Internal inlet check valve

- Inlet filter with clear cover to monitor dust accumulation.

- Each pump generates 173 SCFM.

WORKING UNITS

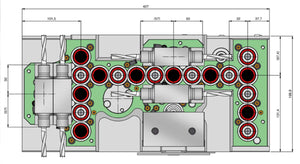

18 TJ boring head with integrated saw unit

- Working unit for vertical and horizontal drilling with18 independent spindles.

- Made in light aluminum alloy with high mechanical properties, the unit is equipped with:

- 18 spindles with vertical outlets in a “T” configuration, 32 mm pitch, of which 8 spindles are along the X axis and 5 spindles along the Y axis on one end of the “T”.

- 2 double-outlet heads for horizontal drilling orientated in "X" axis, 32mm pitch.

- 1 double-outlet head for horizontal drilling orientated in "Y" axis.

- 1 integrated saw unit for 125mm diam. blade in “X” axis.

- All spindles rotate simultaneously and in alternate sequence, right and left. The independent insertion movement of each spindle, by means of pneumatic cylinders, allows both single and multiple drillings.

- Control of the spindles by an electro-valve and cylinder with single thrust chamber for a drilling force of 43kg (95lb) per spindle.

- The working unit is rotated by an asynchronous 2.2 kW (3hp) electric motor controlled by inverter.

- The motor, in turn, activates the transmission made of special steel gears with wide, slanting, rectified and thermally hardened teeth.

- The tool attachment is designed for 10mm cylindrical shanks.

- Vertical spindle stroke 60mm

- Horizontal spindle stroke 75mm

- Busellato utilizes Z-axis pre-setting which pre-positions the drill(s) over the surface of the panel thus saving vertical travel distance when drilling. This feature enhances drilling quality while saving drilling cycle time.

Electrospindle 9.5kW (12.73hp @50Hz) - HSK F63

(pre-arrangement for 4th axis included)

- Mounted directly to the Z carriage, unit slides on linear bearing blocks and two high precision, hardened, steel linear guides which guarantee an equal loading capacity in all 4 directions.

- Tool locking is by Belleville washers, unlocking by pneumatic piston. Three proximity sensors assure correct tool coupling.

- Maximum power 5kW (12.73Hp @ 50Hz)

- Rotation speed 1,000-24,000 rpm.

- Driver three phase motor controlled by inverter

- Rotation sense right and left

- Spindle lubrication permanent greasing

- Front/rear bearings ceramic/ceramic

16-position RotaryTool Changer on the head for high speed tool changes - HSK F63

- Automatic 16 position tool changer for electrospindle with HSK F63 attachment.

- The unit is completely enclosed and opens only during a tool change.

- Equipped with an air blower to guarantee that the cone is clean before being loaded in the electrospindle.

- The unit structure is exceptionally strong to accommodate heavy aggregates.

- Collect pitch 88 mm

- tool diam. 140 mm

FB1108 Movable safety flap curtain to prevent rubbing against delicate surfaces

FB1146 Air conditioning for the electrical cabinet

- Maintains clean, consistently cool air in electrical cabinet

- Keeps humidity low inside cabinet, extending life of electrical components

FB1140 Tool Length Presetting Device

FB1109 Auto-transformer for 208/220/240/408/440/480V 50/60HZ - 30 kVA.

Remote push-button panel

- Axis speed control over-ride

- Includes hook and magnet for easy placement of panel when not in use

- The following redundant controls for convenient operation of the pendulum cycle

- E-stop

- Safety mat reset (after loading part)

- Program start

- Program pause

Infeed lifting table with automatic alignment

Lifting device

The device allows to lift a panel stack up to the worktable height.

Technical features:

- workpiece dimensions (X-Y-Z): 1600-900-10 mm

- workpiece thickness: 30 mm

total workpiece thickness (support panel included): 40 mm - panel stack weight: 3000 kg

- panel stack height: 600 mm

- panel stack misalignment: 30X - 5Y mm

Infeed and alignment device for panels

Automatic device that allows alignment of the panels, available on the stack, with the machine, and to convey them in the work table infeed area. The aligner is equipped with a suction cup for the panel gripping and a system measuring the workpiece surface for the height alignment with the machine.

Suction cups for panel loading

This automatic device takes the workpiece from the infeed position and moves it into the working position. The device includes an air blower that ensures the suction cup grip in high dust conditions.

Max. workpiece thickness: 30 mm (total workpiece thickness, support panel included: 40 mm).

Total weight of the single panel to be loaded = 200 kg

PANEL EVACUATION DEVICE

- for automatic unloading of the nest with integrated dust extraction.

- Automatic evacuation of a 12’ panel after nesting. Mounted on the left hand side of the beam, it slides on pre-loaded ball runner blocks and on two very high precision linear guides made of rectified and hardened steel which guarantee an equal loading capacity in all 4 directions.

- Dust extraction system integrated into the panel evacuation device which cleans the spoil board during the automatic offloading cycle

- The dust extraction system is equipped with an automatic partial selection system.

Belt conveyor for pieces unloading on X=3710 /Y=1620 mm

Motorized system for the transport of machined pieces from the machine to the unloading station. Composed of a belt conveyor with automatic feeding managed by photoelectrical switch, that recognize the pieces on the conveyor. It is possible to manage manually the feeding of the conveyor by push button.

MACHINE CONTROLAND SOFTWARE

NUMERICAL CONTROL

The “Genesis Evolution” Numerical Control incorporates leading-edge, true PC-control on the Busellato, avoiding proprietary PLC control systems. Review major features below and see our website for video tutorials on Genesis Evolution.

- CAD integrated in the control with mirroring, rotation, repetition functions, etc.

- “Multitasking” operating system for using the control even when the machine is working

- Graphical display of the 6 workable faces

- 2D and 3D display of the piece being worked

- Parametric programming which permits the use of mathematical, trigonometric, inverse trigonometric and logical formula and the use of 300 variables.

- Programming on horizontal, vertical faces and virtual faces which can be rotated, very helpful for when using aggregates.

- Programming of linear, circular, oval and ellipse routings on the three Cartesian axes

- Programming of tool radius with automatic correction

- Possibility of excluding the display of some types of machining

- Multi-level zoom function

- Conditioned programming (IF/EndIF Blocks) associated with the use of Macros

- Absolute or incremental programming

- Creating of sub-programs by the operator with the possibility of multiplication, mirroring and rotation of the above

- Up to 10,000 program lines (expandable) are programmable

- Customer can personalize error messages

- Easy identification of stored programs using “preview” function

- Archiving of programs with names up to 256 characters long

- In line recall of the machine set-up and tool specifications

- Management of up to 500 tools

- Graphical display of set up of tool changers

- Tool graphical archive with the possibility of parameterizing up to 9000 different types of tools

- Pocket cycle in defined planes

- Pocket cycle with three modes- Simple pocket, relief and reverse relief

- Programming of all TRUE TYPE ANSI fonts installed in PC (up to 255)

- Linear or curved text orientation

- Management of distances between characters, height, size, bold, italics

- Built-in oscilloscope capable of monitoring the logical input/output status and the dynamic axes’ parameters

- Visualization of the rpm and absorbed current of the aggregates and spindle

- Importation or files from previous Busellato CNC versions (Genesis, Winner90, CNC 90)

- Calculation of time required for program execution

- Program simulation of working cycle

- Manual and machine diagnostic functions in real time with graphic help

- Management and diagnostic synoptics which makes using the machine easier

- Program list management and variable control from the list

- Automatic control of the working speed to optimize the routing path.

FB1255 JET NESTING TrueShape

Advanced Nesting function True Shape integrated on the Jet CAD editor for optimisation of the programmed pieces for Nesting machines. The True Shape function allows free angle positioning and of generic figures within the rectangular Nesting sheet.

Including rectangular Nesting Base and label creation function.

|

SPEC0001 LABELING DEVICE |

|

The label printer is placed on top of the lift table. The lateral alignment device on the lifting surface is equipped with a cantilever structure in extruded aluminum that allows you to transport the pad for applying the labels. The application of the labels is possible on the maximum allowed size (length / width). The label application pad consists of a rubber-coated plate equipped with a vacuum tube system for holding the label and a sensor that allows to detect the presence of the label. The sensor also detects any anomalies that occur during the labeling cycle: • label not detached from the pad after application • label not picked up by the printer • label selected but lost before application • label applied Features: - average labeling time: 6 s / label - rotation of the label 0 ° or 90 ° according to the labeling program - label application accuracy: ± 5 mm (± 0.2 inch) The labels have the following dimensions (X-Y): - 65 x 45 mm - 100 x 30 mm - 100 x 80 mm - 80 x 140 mm N.B. label printing software not included

|

FB1394 Seaworthy packing