-

WOODWORKING

-

METALWORKING

- PLASTICS / COMPOSITES

- DUST/CHIP SYSTEMS

-

POSITIONERS

-

PARTS AND TOOLING

-

SUPPORT

-

TRAINING

-

PRE-OWNED MACHINES

$86,449.00

| /

To see the entire line of LIBRA sanders and options CLICK HERE FOR BROCHURE.

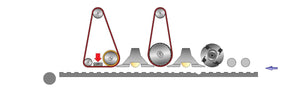

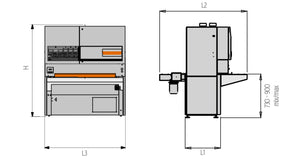

The LIBRA 45 RTC 110 is a 43” three head combination planer sander specifically designed for calibration and sanding of wood based panels with the ability to sand veneered panels. The Libra 45 offers the highest degree of finish quality for the medium to large factory. This combination sander offers some of the best technology in its class wrapped in a tank like super structure.

|

PLANER UNIT: |

|

|

CA7277 |

· Helical cutter block Ø 140mm o 312 four sided disposable knives 14x14x2 o 62 anti kickback fingers o Infeed pressure bar with two section plates

|

|

SANDING UNITS: |

|

|

Unit 1: |

· Contact Roller o Steel grooved x 140 mm (5 ½ ”) dia. o Pneumatic positioning |

|

Unit 2: |

· Combination Sanding Head o Rubber covered 45 Shore x 140 mm (5 ½ ”) dia. o Extractable rigid flat platen (density = 0.68) o Pneumatic positioning |

|

TECHNICAL DATA: |

|||

|

· Working width |

1100 mm |

43” |

|

|

· Working thickness |

4 - 170 mm |

¼ – 6½” |

|

|

· Abrasive belt size |

1115 x 2150 mm |

43” x 84” |

|

|

· Variable Feed speed |

3.5 – 18mpm |

11.5 – 59 fpm |

|

|

· First unit motor |

|

25Hp |

|

|

· Second unit motor |

|

25Hp |

|

|

· Feed belt motor |

|

3 HP |

|

|

· Compressed air pressure |

6 bar |

90 psi |

|

|

· Compressed air consumption |

40 NL/min |

2 cfm |

|

|

· Dust extraction velocity |

20 mps |

65 fps |

|

|

· Dust extraction volume |

3180 m3/h |

1872 cfm |

|

SPECIFICATIONS

Standard Equipment

- Welded structural tubular steel frame

- Infeed table w/ variable feed speed

- 2 idle infeed and 2 idle outfeed rollers

- Natural (live) rubber profiled conveyor top

- Powered thickness adjustment

- Infeed pressure roller w/ anti kick-back system

- Automatic conveyor belt tacking

- Automatic break on all units

- Grooved steel contact roller 140 mm (5½ ”) diam.

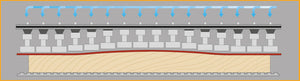

- Combination Sanding Head

- Rubber covered contact roller 140 mm (5 ½ “) 45 sh.

- Platen made of extractable bar (density D=0.68)

- Steel backed felt pad w/ graphite cover

- Pneumatic abrasive belt tensioning

- Micrometric height adjustment on all units

ELECTRICAL DATA:

- 230V – 3 Ph – 60 Hz

- Safety switches on all hinged doors

- Automatic Star-delta Start

- Overload protection

- Main switch lock out

|

CA6288 |

USA safety standards |

CA4293 |

Variable controlled feed motor, 2 Hp 3.5 to 18 m/min |

|

CA3506 |

Version “y” |

CA8206 |

Motor upgrade, 1st head 25 Hp |

|

|

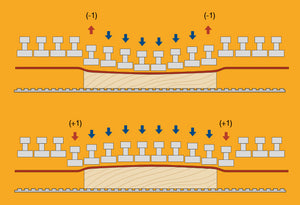

Pneumatic selector 1st and 2nd units from control. Electronic worktable positioning device. |

CA8210 |

Motor upgrade, 2nd -3RD head 25 Hp |

|

CA5291 |

Electronic digital thickness readout in inches |

CA2585 |

Pneumatic adjustment for pressure shoe in 2nd Position |

|

CA5562 |

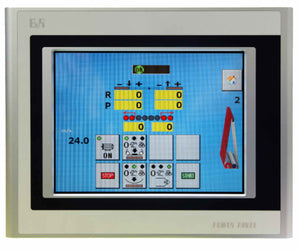

FOX 1000 S Electronic control |

CA5254 |

Infeed and outfeed rollers for long and short pieces |

|

CA3649 |

Eco System Package |

CA7277 |

Planer Unit |

|

CA5205 |

Oscillating belt cleaning blower on 2nd head |

CA5207 |

Oscillating belt cleaning blower on 3rd head |

|

CA6262 |

Floating pressure shoe 2nd Position |

CA6263 |

Floating pressure shoe 3rd position |

|

CA5687 |

Door with window for sanding head inspection |

CA5686 |

LED internal lighting |

|

CA9225 |

Seaworthy packing “version 110” |

CA7205 |

230 VOLT |

|

· Automatic Disc Braking System o Pneumatically operated o Failsafe design |

|

|

· Infeed feed roller system o Anti kick-back system o Protects operator |

|

|

· Planer Unit o Helical cutterblock Ø 140 mm o 312 four sided knives o 62 anti-kickback fingers o Infeed bar with 2 sectional plates o Front access door for easy access to knives o On/off selector switch on front panel |

|

|

· Floating Pressure shoes in the 2nd and 3rd positions o Equipped with steel linings o Rubber coated pressure rollers

|

|

|

· Automatic Feed Belt Tracking o Electronically controlled o Pneumatically operated o Continuous tracking o Over tracking override |

|

|

· Pneumatic on/off Positioning o In lieu of manual positioning o For all three Units |

|

· Fox 1000S control o 5.7” color LCD display o Controls the automatic rise and fall of the platen and a contact roller. o Total control of electronic segmented platen, excluded, flat with all sections activated and segmented activated by geometrical shape of the work piece. o Automatic sequential motor start-up o Management and control of the feed speed o Activation and control of blower timing for belts o Reverse control of the belts o Bar chart graphic showing sanding belt wear. o Reprts for machine activity and production o Management of machine alarms and self diagnostics of the electronic cards.

· Feed conveyor electronic speed variator o 3Hp o Adjustable from 11.5 to 59 ft / min.

|

|

|

· Extended Infeed and Outfeed Support o 5 idle rollers on the infeed o 4 idle rollers and 1 power roller on the outfeed |

|

|

· Worktable rise and fall o The table is supported by 4 large jackscrews to prevent table movement and allows for long lasting tolerances an levelness

|

|

-

Oscillating belt cleaning blowers on both sanding heads

- Timed intervention divided into 2 macro areas activated by the part as if feeds through the machine

- Electronic oscillation

- Dust extraction hood

- Filter and pressure adjustment

WARRANTY:

Seller warrants, for a period of one (1) year beginning on the date the Machinery is accepted, that the Machinery will be free of defects in workmanship and materials, excluding belts, bearings, and common electrical parts, which carry a six-month warranty. This warranty does not include parts consumed during normal operation (wearable items), working units, or maintenance required in the ordinary course of operation. Seller shall warrant any replacement spare parts and accessories installed pursuant to this warranty for the period of ninety (90) days.

TOOLING:

Tooling, including blades, is not included unless noted. Upon request, we can supply a quotation of the most suitable tools required for use on this machine.